Prototool Manufacturing Limited is a company specializing in injection mold services. Injection molding is a manufacturing process that involves the injection of molten material into a mold cavity. The molten material is then allowed to cool and solidify, resulting in a finished product.

Injection molding is a popular manufacturing process because it can produce large quantities of high-quality parts quickly and efficiently. It is used in a wide range of industries, including automotive, medical, aerospace, and consumer goods.

At Prototool Manufacturing Limited, we use state-of-the-art equipment and techniques to ensure that our injection molding services meet the highest standards of quality and precision. Our team of experienced engineers and technicians work closely with our clients to develop custom molds that are tailored to their specific needs.

We offer a wide range of injection molding services, including prototyping, production, and assembly. Our prototyping services allow clients to test their designs and make any necessary modifications before moving on to full-scale production. Our production services are designed to produce large quantities of high-quality parts quickly and efficiently, while our assembly services ensure that all parts are properly assembled and ready for use.

We are committed to providing our clients with the highest level of customer service and satisfaction. Our team is dedicated to ensuring that each project is completed on time and within budget, and we work closely with our clients to ensure that their needs are met throughout the entire process.

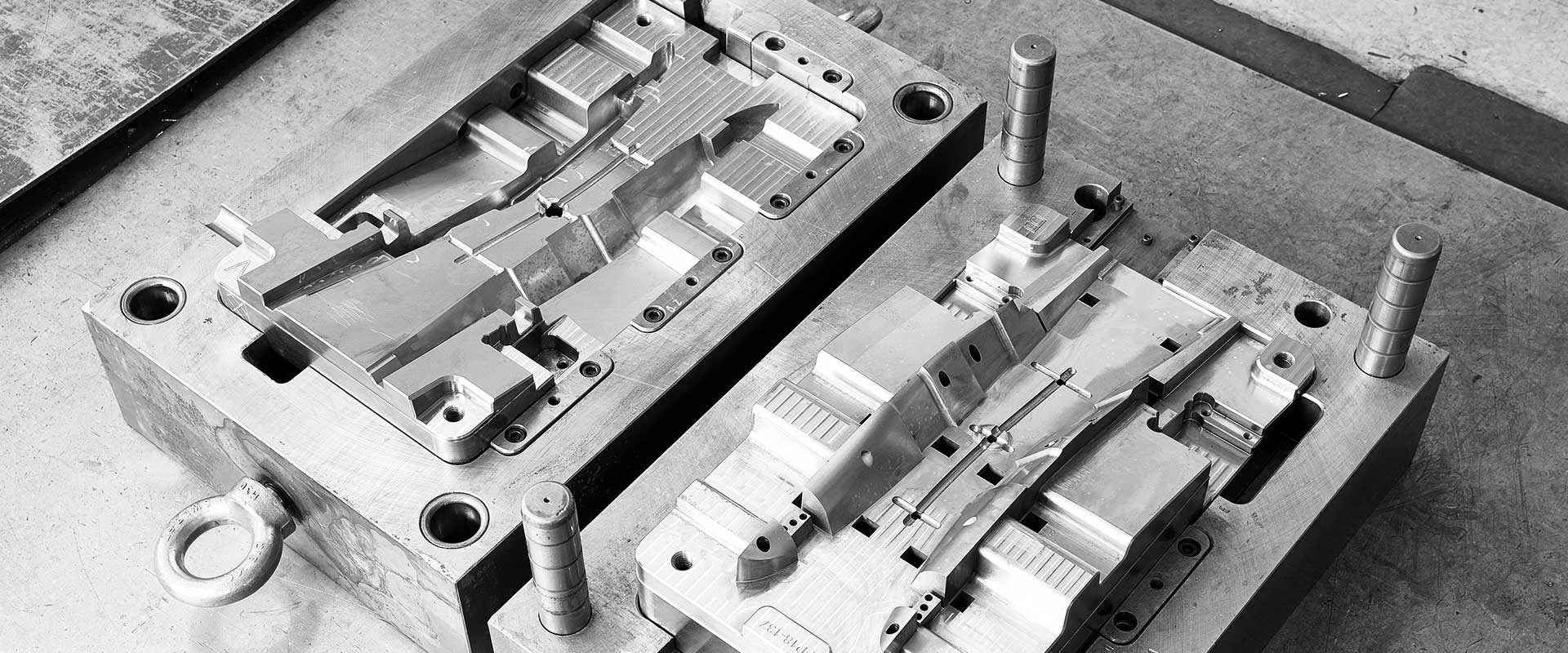

Auminum Injection Mold is a manufacturing process that involves injecting molten aluminum into a mold cavity to produce a specific part or product. It is a popular manufacturing method for producing small to medium-sized parts with high precision and accuracy.

The process involves melting the aluminum material and injecting it into the mold cavity under high pressure. The molten aluminum fills the cavity and takes the shape of the mold, which is usually made of steel or other durable materials. The aluminum then cools and solidifies, after which the mold is opened, and the part is removed.

The advantages of aluminum injection molding include its ability to produce complex parts with tight tolerances, excellent surface finishes, and high production rates. It is also a cost-effective alternative to other manufacturing methods like CNC machining or die casting.

Some common applications of aluminum injection molding include producing parts for the automotive industry, electronics, and consumer goods.

If you are in need of injection molding services, look no further than Prototool Manufacturing Limited. With our state-of-the-art equipment, experienced team, and commitment to quality and customer service, we are the ideal partner for all of your injection molding needs. Contact us today to learn more about our services and how we can help bring your ideas to life.

Leave a comment